By Volha Hurskaya

How systematic thinking and digital tools transformed an unorganized industry into a predictable, client-focused service sector

Commercial refrigeration service in emerging markets often develops without the institutional frameworks found in established economies. According to a recent Georgia Today report, In Georgia, this sector has undergone significant transformation over the past decade, evolving from individual service provision to systematic business models that emphasize digital coordination and standardized quality protocols.

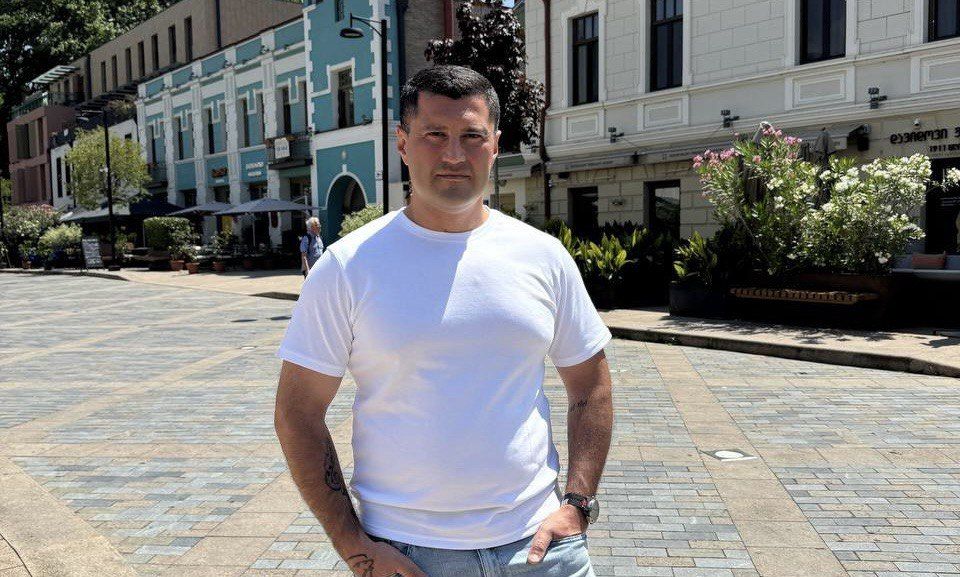

Erik Arutinyan, founder and CEO of LTD E.D.E., has spent seventeen years systematically building order from this chaos. His methodical approach to creating standards, implementing digital coordination, and establishing predictable service delivery has not only built Georgia's leading refrigeration service company but fundamentally changed how the entire industry operates. Where once scattered individual repairs existed, now stands a systematic sector with clear quality benchmarks and professional standards.

Building Professional Standards

When Arutinyan established his business, he faced specific institutional challenges. The numbers painted a stark picture: Georgia's commercial refrigeration sector in 2007 operated without any professional associations, certification programs, or standardized training. Service calls averaged 48-hour response times, with a 40% callback rate due to inadequate repairs. For businesses storing temperature-sensitive products, this meant constant risk.

"At the time of founding the company, there was no proper refrigeration service industry in Georgia - no personnel, no culture, no logistics," he explains. "Everything had to be built from scratch, without ready models or support." The limited institutional support also affected professional perception, with technicians often viewed as second-class workers rather than skilled professionals.

"During a financial crisis around New Year's, when client payments were delayed as often happens in our country, I faced an impossible choice: leave my employees without salaries during the holidays or find another solution," Arutinyan reveals. "My wife and I decided to sell our car to ensure our team received their salaries. I don't regret this decision for a second - it was my duty as a leader. This principle of taking responsibility for your people became the foundation of everything that followed."

Building Systems from Scratch

Recognizing that sustainable business requires systematic approaches, Arutinyan began developing frameworks that would eventually transform the entire sector. His first priority was creating predictable service delivery through standardized procedures, trained personnel, and reliable communication systems.

The CRM system Arutinyan created extended far beyond basic appointment scheduling. Key features included:

- Real-time service tracking allowing clients to monitor repair progress and completion status (pioneering technology for Georgia's maintenance sector)

- Automatic parts management linked to repair completions

- Customer dashboards displaying technician whereabouts and arrival estimates

- Proactive maintenance notifications driven by equipment history and utilization data

The commitment: 18 months of programming and approximately 30% of yearly earnings. The outcome: response windows contracted to 24-48 hours, while rivals continued with 'we'll arrive eventually' approaches.

The platform's impact was immediate and measurable. Response times dropped to 24-48 hours. Repeat service calls decreased by 50% through better initial diagnostics and repair quality. Client satisfaction reached 95%+ through transparent communication and predictable service delivery.

More importantly, the digital system tracked every repair with serial numbers and failure causes, creating comprehensive equipment histories. This data revealed seasonal patterns – summer breakdowns cost clients significantly more due to increased frequency. Arutinyan developed an innovative insurance-style solution: Clients gained predictable budgeting while E.D.E. managed seasonal risk variations through data-driven pricing models.

Creating Industry Standards Through Innovation

Where the chaotic market offered only reactive repairs, Arutinyan developed comprehensive equipment refurbishment services that provided systematic alternatives to expensive replacements. His approach involved complete technical analysis, selective component replacement, and performance optimization that delivered 70% cost savings compared to new equipment purchases.

"Initially, the refurbishment idea was met with doubt," Arutinyan recalls. "Clients couldn't understand why they should modernize a refrigerator when they could simply buy a new one. We had to work almost at a loss initially to prove the value." The systematic refurbishment process he developed became the new industry standard, with competitors attempting to replicate both the methodology and results.

This innovation exemplified Arutinyan's approach to building order from chaos: identify inefficiencies in existing practices, develop systematic solutions, and demonstrate superior results through consistent execution.

Systematic Team Development

Understanding that sustainable industry transformation required skilled personnel, Arutinyan personally developed E.D.E.'s core technical team through systematic training programs. "I always operated on the principle that a real man and real leader is someone who takes responsibility," he explains. "For the business, for people, for results. This became my management style and the source of trust within the team."

His training methodology combined technical skill development with systematic thinking and quality standards that were previously unknown in the market. Many team members have remained with E.D.E. for over ten years, creating institutional knowledge that maintains service quality even as the company scales operations.

This systematic approach to human capital development has become another industry benchmark. Competitors regularly attempt to recruit E.D.E. personnel specifically to learn the company's systematic approaches to service delivery and quality management.