What If iPhones Were Made in America? Trump’s Push & Apple’s Dilemma

When former President Donald Trump repeatedly demanded that Apple manufacture its iconic iPhones in the United States, it sparked a wave of speculation: Could Apple really do it? And if so, what would it cost consumers?

Apple, a symbol of American innovation, largely relies on a global supply chain, especially China. Despite political pressure and rising geopolitical tensions, Apple has stayed the course. Here's why moving production to the U.S. isn’t so simple or cheap.

How Much Would an iPhone Cost if Made in the USA?

If Apple moved iPhone production entirely to the U.S., the cost of an iPhone could skyrocket. Current estimates suggest that manufacturing the device in America could increase the retail price by $100 to $200, depending on the model.

Why? Several factors:

-

Labor Costs: U.S. factory wages are substantially higher than in China or Vietnam.

-

Supply Chain Efficiency: Apple’s current suppliers are mostly located in Asia. Replicating that infrastructure domestically would take years — and billions of dollars.

-

Manufacturing Volume: China can scale up fast with massive factories like Foxconn's, employing hundreds of thousands. The U.S. doesn't have a comparable workforce for tech assembly.

A standard iPhone 15 Pro that sells for $999 today might jump to $1,200 or more under a fully American-made model.

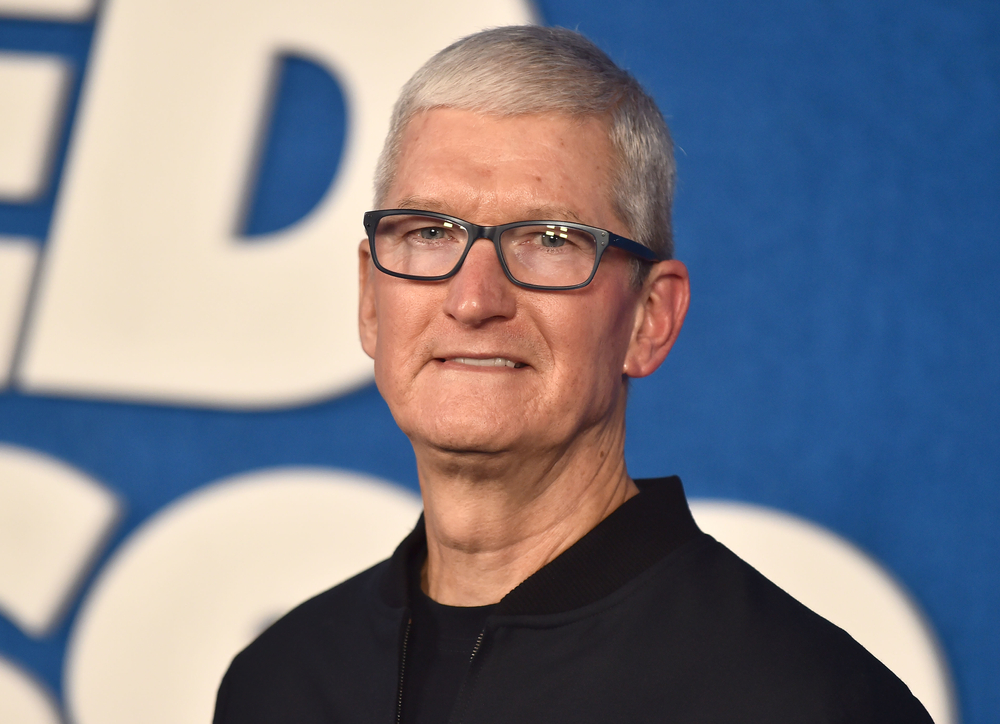

Related: John Ternus: The Man Who Could Succeed Tim Cook as Apple CEO

Related: Trump’s Tariffs vs. Apple: Will Your Next iPhone Cost More?

Why Doesn’t Apple Manufacture iPhones in the USA?

Apple does design its products in California — but building them in America is another matter. Here's why the company resists:

-

Specialized Labor: Countries like China have a highly skilled, specialized workforce for electronics assembly. That expertise doesn’t exist at the same scale in the U.S.

-

Speed and Flexibility: Asian suppliers can adapt quickly to design changes or production increases. U.S. facilities lack this flexibility.

-

Cost and Margin Protection: Apple’s profit margins rely on cost efficiency. U.S. manufacturing would erode those margins — or force higher prices.

Apple has made small moves to localize certain aspects, like chip manufacturing in Arizona through its partnership with TSMC. But for now, full-scale U.S. iPhone production remains highly unlikely.

Conclusion

Trump’s push to “bring Apple home” made headlines, but the economics tell a more complicated story. While manufacturing iPhones in the U.S. may sound patriotic, it would be prohibitively expensive, logistically challenging, and ultimately passed on to the consumer.

Globalization may have its critics, but in Apple’s case, it’s also the reason your iPhone doesn’t cost $2,000.